15311826613

Click to add WeChatIlmenite is an oxide of iron and titanium, and is the main mineral for extracting titanium or titanium dioxide. With the increasing demand for titanium resources in various fields, titanium recovery from ilmenite has gradually entered the field of vision of mineral processing professionals.

However, ilmenite is recognized as a difficult ore to be processed. If you want to obtain an ideal titanium recovery rate, the choice of mineral processing technology is very important. At present, flotation is commonly used to complete titanium separation. Below we introduce ilmenite beneficiation from three aspects: ilmenite flotation, agents and process.

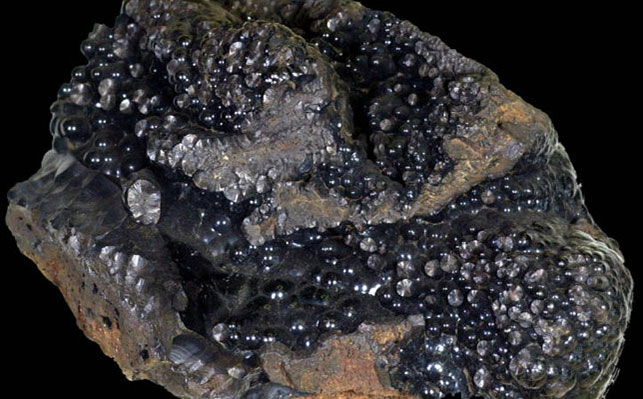

(Ilmenite Ore, picture from the Internet)

When using flotation to select ilmenite, due to the ore properties of ilmenite, pre-enrichment treatment is required before selection, and then flotation is used to complete the selection.

Pre-enrichment can be done by shaking table pre-recovery, magnetic pre-enrichment, and microwave pre-treatment.

Pre-recovery of shaking table: The tailings of shaking table have low grade and can be discarded as gangue; the ore yield of shaking table is high and the grade is high, which can be directly used for the next stage of selection; after the ore of shaking table is regrinded, the amount of flotation collector used is significantly reduced compared with that before grinding; the flotation of shaking table ore products after grinding can not only obtain qualified ilmenite concentrate, but also reduce the amount of reagents used and reduce the cost of mineral processing.

Magnetic separation pre-enrichment:Magnetic minerals such as ilmenite are enriched through strong magnetic separation to increase the grade of the original ore.

Microwave pretreatment:It can accelerate the oxidation of ferrous ions on the surface of ilmenite into trivalent ferrous ions, strengthen the adsorption of oleate ions, and thus improve the recovery rate of fine ilmenite.

With the increasingly prominent problems of poor, fine and impure ore, the beneficiation and recovery of fine-grained ilmenite resources is particularly important. At present, flotation is mostly used for beneficiation and recovery of titanium resources, which can not only achieve efficient recovery of fine-grained ilmenite, but also simplify the process flow.

The purpose of flotation is mainly to desulfurize. The sulfide content in the pre-enriched concentrate is relatively high, generally dominated by pyrrhotite, and there are also a small amount of cobalt-nickel pyrrhotite, pyrite, sulfide-cobalt ore, sulfide-nickel-cobalt ore, chalcopyrite and black copper ore.

If these sulfides are not separated before titanium selection, most of them will enter the titanium concentrate, resulting in a significant decrease in the grade of the titanium concentrate and a greatly exceeded sulfur content, which seriously affects the subsequent operation of ilmenite. Therefore, yellow medicine is often used for flotation desulfurization.

Flotation reagents are an important part of assisting flotation to complete the selection. Commonly used mineral processing reagents include collectors and adjusters.

The main function of the collector is to enhance the hydrophobicity of the mineral surface and increase the flotation effect. Using sodium oleate as a collector can improve the floatability of ilmenite and achieve good flotation of ilmenite. However, with the consumption of resources, the utilization of difficult-to-select ilmenite has become inevitable, which puts forward new requirements for flotation agents. The selectivity of a single collector is often insufficient, and many conventional collectors are also difficult to achieve ideal indicators. In order to improve the flotation effect and meet industrial indicators, combined collectors are often used to complete flotation.

Gangue minerals such as pyroxene, olivine and chlorite have an adverse effect on the flotation of ilmenite. Therefore, regulators are often used to improve flotation conditions during flotation. Regulators are divided into two categories according to their functions, namely activators and depressants.

Activator: Increase the floatability of ilmenite. Commonly used activators include Pb(NO3)2;

Depressor: Inhibit the floating of gangue minerals. Commonly used depressants include water glass, sodium fluorosilicate, acidified water glass, carboxymethyl cellulose (CMC), sodium hexametaphosphate and oxalic acid.

Different raw ores are combined with different process flows to flotate ilmenite, and the indicators obtained are different. Therefore, the selection of process flow is also particularly important. Proper process selection can greatly improve the subsequent flotation indicators. However, flotation cannot completely obtain qualified titanium concentrate. It is necessary to use a variety of different process components to form a combined process to effectively obtain titanium.

Currently, the commonly used ones are magnetic separation-flotation process flow, strong magnetic-grinding-flotation process flow, magnetic separation-gravity separation-flotation (one rough, two fines, and one sweep) process flow, two-stage strong magnetic-flotation (one rough, one sweep, and three fines) process flow, etc.

The above is an introduction to ilmenite beneficiation methods, beneficiation reagents and common beneficiation process. In actual beneficiation plants, due to the different ilmenite ore components, the beneficiation processes are different. For specific selection, it is necessary to conduct beneficiation test analysis first, and then design suitable beneficiation process and suitable ilmenite beneficiation equipment for it through analysis to obtain an ideal return on investment.