15311826613

Click to add WeChatNepheline is similar to feldspar minerals. Nepheline has high sodium and potassium content. It often coexists with dark minerals such as pyroxene, biotite, and iron oxides. The content of these associated components is often more than 10%. Therefore, it is not economical to use the raw ore directly for aluminum smelting. In addition, the raw ore has a high iron content and cannot be directly used in the glass industry. The dark minerals in the raw ore must be removed through ore dressing to improve the economic benefits of nepheline. The following article introduces the nepheline ore iron removal and purification process process with a case study!

(Nepheline mine, picture from the Internet)

The nepheline mine is located in the Proterozoic strata. The basic-alkaline complex intruded along the structure near Pinghe. The alkaline complex is nepheline syenite, which is composed of rock bodies in the nepheline, neon and phosphorite phases. This type of rock is the final product of the crystallization differentiation of the alkaline rock complex. The rock body is rich in sodium oxide and poor in silicon dioxide, forming a large amount of nepheline. The ore is white and light gray, with black spots, coarse particles, and pegmatite structure.

The mineral composition is 88.8% nepheline, 2.8% titanium pyroxene, 2.2% biotite, 0.7% muscovite, 1.9% calcite, 0.4% apatite, and 3.2% hematite, limonite, siderite, titanite, aegirine, garnet, zircon, and sulfide minerals. The particle size of nepheline is generally 0.2-1.0mm, containing 0.09% iron oxide. The mineral purity is not enough, and it still contains trace intergrowths. Nepheline ore contains a small amount of iron-containing minerals, such as black (white) mica, and isomorphous replacement iron.

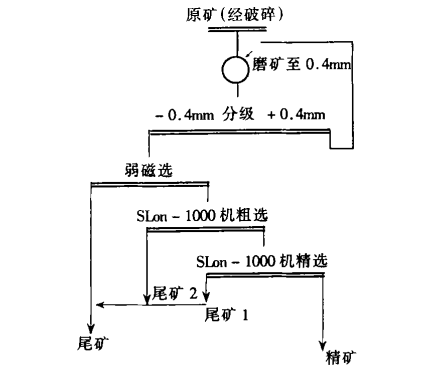

Nepheline, feldspar, muscovite, calcite, zircon and other minerals in the nepheline ore are all non-magnetic minerals, and the others are weakly magnetic minerals. Through strong magnetic separation, nepheline and other minerals can be separated from weakly magnetic dark minerals, but the degree of separation is different. Biotite and iron oxide are easier to separate, while titanium pyroxene is more difficult to separate. Therefore, through the analysis of ore dressing tests, a one-rough and one-fine process consisting of a high gradient magnetic separator was designed for it.

Process flow: Jaw crusher and rod mill are used to complete the crushing and grinding, and the crushing and grinding to 0.3-0mm particle size are used for magnetic separation. The magnetic separation adopts SLon-1000 magnetic separator, with a pulsating mechanical stroke of 3mm, 150 strokes/min, slurry flow rate of 3cm/s, and a stainless steel coarse mesh as the separation medium. The magnetic field strength of the primary roughing is 1.0T.

The iron content of the products with 0.25-0.04mm in the non-magnetic concentrate is low, while the iron content of the products with too coarse and too fine is high. This is mainly because the coarse products have more intergrowths and the iron-containing mineral part is not cleaved by monomers, while the iron-containing mineral mud part is concentrated in this particle size and is mixed with the concentrate or adhered to the concentrate particles during sorting.

Finally, through SLon high-gradient magnetic separation, one coarse and one fine separation, a nepheline concentrate containing Fe2O3<0.2% was obtained.

The above introduces the beneficiation process of a certain nepheline. In actual beneficiation, how to determine the nepheline process needs to be designed according to the beneficiation test analysis, and a suitable and reasonable process scheme should be selected to effectively obtain the ideal concentrate and improve the return on investment.