15311826613

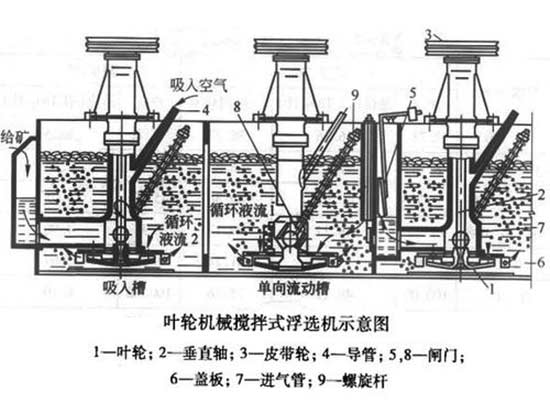

Click to add WeChatWhen the mechanical agitation flotation machine is working, the sludge and chemicals are fully mixed and then fed into the bottom of the first chamber of the flotation machine. , the impeller of the flotation machine rotates, forming a negative pressure in the wheel cavity, so that the slurry at the bottom of the tank and in the tank are brought into the mixing zone by the lower suction port and the upper suction port of the impeller respectively, so that the air enters the mixing zone along the air guide sleeve, and the slurry, This is where the air and medicine mix. Under the action of the centrifugal force of the impeller, the mixed slurry enters the mineralization zone, and the air forms bubbles and is crushed. It fully contacts the coal particles to form mineralized bubbles, which are evenly distributed in the tank under the action of the stator and turbulent plate. cross section, and moves upward into the separation zone, where it is enriched to form a foam layer, which is discharged by the foam scraper to form clean coal foam. The unmineralized coal particles on the bottom of the tank will be mixed, mineralized and separated again through the circulation hole and the upper suction port. The part of the slurry under the tank that has not been sucked in by the impeller of the flotation machine enters the bottom of the tank in the second chamber through the medium ore box buried in the slurry. After completing the entire process in the first chamber, it enters the third chamber. The flotation machine repeats in each tank. The operation continues until the mine enters the last chamber and the flotation process ends and the resulting tailings are discharged into the tailings box.

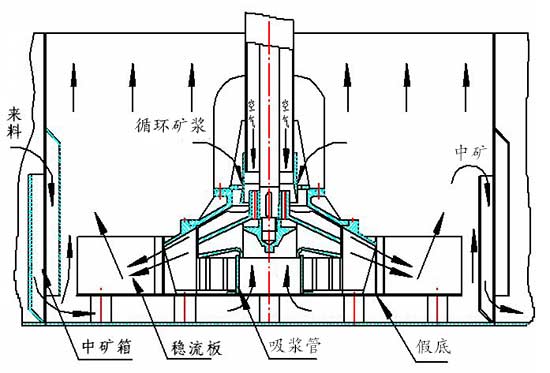

When the inflatable agitated flotation machine works, it relies on the motor The transmission device and the hollow main shaft drive the impeller to rotate. The slurry in the tank is sucked into the space between the lower blades of the impeller from all sides through the bottom of the tank through the inner edge of the lower blades of the impeller. At the same time, the low-pressure air supplied from the outside enters the air distribution in the lower impeller cavity through the cross beam, air regulating valve, and hollow spindle. and then enters between the lower blades of the impeller through the small holes around the air distributor. After the slurry and air are fully mixed between the lower blades of the impeller, they are discharged from the outer edge of the lower blades of the impeller.

Due to the joint action of the rotation of the impeller of the flotation machine, the cover plate, and the central cylinder, a certain negative pressure is generated in the upper blades of the impeller, causing the medium ore foam and feed ore to flow through the middle ore pipe and the ore feed pipe. It enters the central cylinder, enters between the upper blades of the impeller, and is finally discharged from the outer edge of the upper blades. The mixture of slurry and air discharged from the outer edge of the lower blade of the impeller and the medium ore and feed ore discharged from the outer edge of the upper blade of the impeller enter the main body of the slurry in the tank after being stabilized and oriented by the stator installed around the impeller. The mineralized bubbles rise to A foam layer is formed on the surface of the slurry. Part of the slurry returns to the lower blades of the impeller for recirculation, and the other part enters the next tank through the flow hole on the wall between the tanks for re-sorting or is discharged as a certain result product.

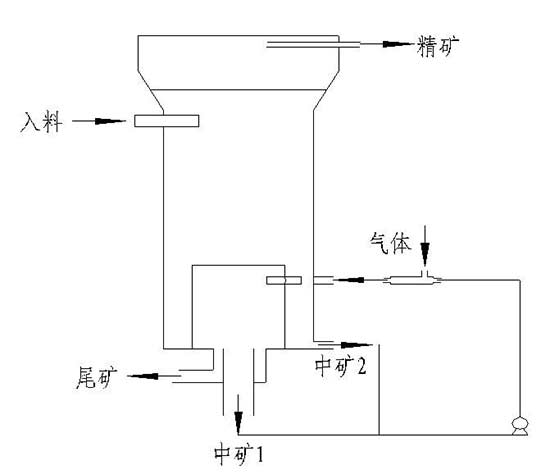

When the mining impeller flotation machine works, the slurry enters the The tube is fed into the impeller, and is thrown into the groove by the centrifugal force generated by the rotating impeller, so a negative pressure is formed under the cover, and air is automatically sucked in from the intake tube. The sucked air and the fed slurry are mixed together at the upper part of the impeller and thrown into the tank, again generating negative pressure, sucking in the air, and so on continuously. In the slurry treated with the drug, the floating minerals are brought to the surface by bubbles to form a mineralized foam layer, and are scraped out by the scraper to obtain the concentrate. The non-floating minerals and gangue enter the intermediate chamber through the gate on the side wall of the tank and are fed into the next flotation tank. The adjustment of the slurry level in each or several tanks can be completed by adjusting the gate up and down. The cycle process is completed in the machine.

The rod flotation machine drives the lower part of the hollow shaft with the help of motor and pulley When the installed inclined rod wheel rotates at high speed, negative pressure is generated in the flotation wheel. The air is sucked in through the hollow main shaft and divided by the flotation wheel, and dispersed into tiny bubbles. Due to the strong stirring and ejection of the flotation wheel, the slurry and air are fully mixed. Under the action of the inclined rod of the flotation wheel, this slurry-gas mixture is first pushed forward, and then relies on the boss (gland) and the arc plate. The diversion effect of the flow stabilizer makes it continuously and evenly distributed in the tank. Finally, under the reflection effect of the tank bottom and tank wall and the flow stabilizing effect of the arc plate, the ore liquid level rises from the stirring area through the sorting area. The flow trajectory of the slurry-gas mixture forms a "W" shape when viewed from the longitudinal section of the tank. This flow characteristic makes the range of the stirring zone relatively expanded and the range of the sorting zone relatively reduced. In addition, the shallow tank makes the range even narrower. The former increases the chance of contact between mineral particles and bubbles, which is beneficial to the mineralization of foam. The mineralized foam rises to the foam area and is scraped out by the scraper to become foam products. The working principle of the suction tank is the same as that of the vertical sand pump, that is, with the help of the rotating lifting wheel to generate a pressure head, the slurry is sucked from the diversion pipe at the bottom of the tank and lifted to the required height.

The above is an introduction to the working principle of common flotation machine equipment. If you want to know more about flotation machine, please check it out (Product knowledge). If you want to inquire about flotation machine equipment, please call: 15311826613! Xinhai helps you customize flotation machine equipment and flotation machine process to help you avoid various problems in the mineral processing plant, improve mineral processing efficiency, and ensure return on investment.