15311826613

Click to add WeChatThe Pakistan copper ore beneficiation project undertaken by Xinhai Mining is a service project for the entire mining industry chain, that is, a one-stop service of "design and research, complete equipment manufacturing and procurement, commissioning and delivery, mine operation and management". Services include: mineral processing tests, mine design, equipment manufacturing and procurement, packaging and shipping, installation and commissioning, worker training, meeting standards and production, mine management and ore operations.

The person in charge of the copper mine project wants to use advanced technology and equipment to build a modern mineral processing plant. By chance, they met Xinhai and found that Xinhai's service model was exactly what they were looking for. After detailed understanding and multi-party communication, we decided to sign a service contract with Xinhai Mining Equipment.

Ore processing capacity: 1500TPD

Ore properties: The mineral composition of the project’s ore Relatively simple, the metallic minerals are mainly chalcopyrite, pyrite, etc. Non-metallic minerals are mainly quartz, chlorite, etc. The copper grade of the raw ore is 0.80%, and copper is a valuable element that can be recycled.

Xinhai Research Institute provides copper ore beneficiation test services and customizes a suitable process for it based on the test results. The process consists of two and a half closed-circuit crushing stages - one closed-circuit grinding and classification process - one rough separation, two sweeps, two fine flotation stages - two stages of mechanical dehydration.

According to the test plan given by the institute, Xinhai Mining Design Institute conducted a feasibility study on the test plan and customized the preliminary design and construction drawings of the mineral processing plant.

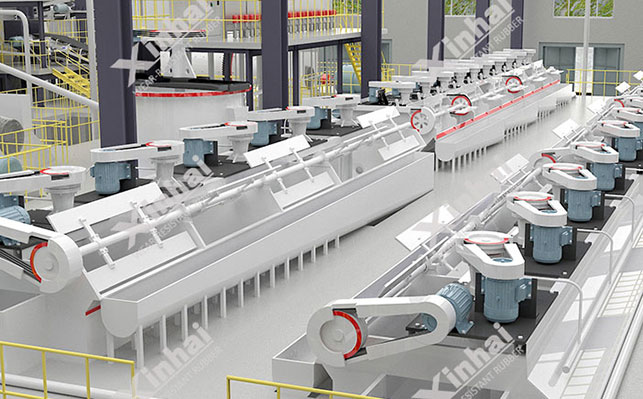

Xinhai Machinery Design Institute completed the production and procurement of mineral processing equipment. Xinhai produced wet grid ball mills, linear vibrating screens, hydrocyclone units, and XCF flotation machines, KYF flotation machine, BF flotation machine, high-efficiency transformation of concentrator, and purchase of cone crusher, chamber filter press and related accessories and auxiliary parts.

Xinhai Mining provides the packaging design and shipping design of the goods for the dressing plant. According to the general layout of the construction site, the packaging of each work area is determined and accurate The unloading position eliminates the inconvenience caused by secondary transportation and hoisting, and is conducive to on-site management and improving work efficiency during installation.

The Xinhai installation and debugging team will rush directly to the copper ore dressing site from the date of shipment. , prepare to start the installation and commissioning matters related to the mineral processing plant, implement the installation and commissioning plan in advance, and carry out equipment installation operations at any time when the equipment arrives at the processing plant. In addition, Xinhai will subsequently complete worker training, mine management and mine operations.

In the end, the project completed all operations in a short construction period and entered the production and operation stage ahead of schedule. Since it was put into operation, the entire processing plant has been operating stably, the equipment quality is reliable, and the indicators and economic benefits of each processing plant have reached the ideal and expected goals of customers.

Recently, Xinhai Mining Equipment also received a letter of thanks from the customer. The letter praised Xinhai Mining Equipment’s process debugging team for their skilled professional skills, meticulous professional attitude and high sense of responsibility, and served both parties The subsequent cooperation laid a solid foundation.