15311826613

Click to add WeChatAbout 90% of my country's iron ore is poor ore resources, but the scale of beneficiated iron ore resources is large and relatively abundant. Effective beneficiation technology can better obtain ideal iron concentrate. From the ore type, the main mineral types for obtaining iron are magnetite, hematite and limonite. The process methods are different, but the process is basically the same.

At present, the common iron ore beneficiation process is grinding-beneficiation process, among which the grinding process mostly adopts two-stage grinding process, and small and medium-sized beneficiation plants mostly adopt one-stage grinding process. The classification after grinding basically uses spiral classifiers. In order to improve work efficiency, some beneficiation plants use hydrocyclones instead of secondary spiral classifiers; and the beneficiation process varies according to the properties of the ore. Let's take a look at the different iron ore beneficiation process flows.

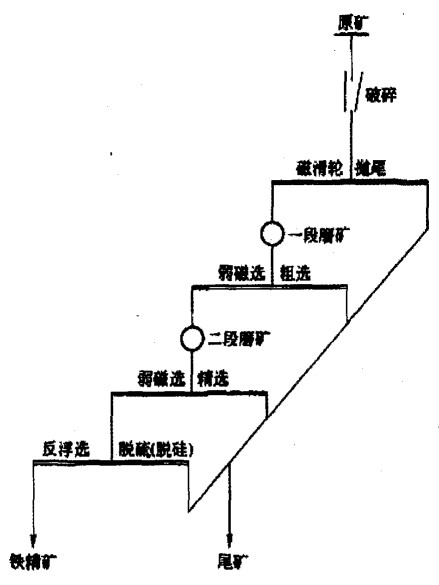

The iron content of magnetite is about 80%. Because of its strong magnetism, the main beneficiation process is magnetic separation. Before entering the beneficiation, the raw ore can be coarsely or medium crushed, and the magnetic pulley can be used to pre-discard the tailings and throw out the surrounding rock to reduce the amount of ore entering the mill and reduce the beneficiation cost. The process flow is mostly dry pre-discarding-stage grinding-stage classification process. The final raw ore iron grade is 23.44%, and the concentrate iron grade is 64.18%, and the iron recovery rate is 73.74%.

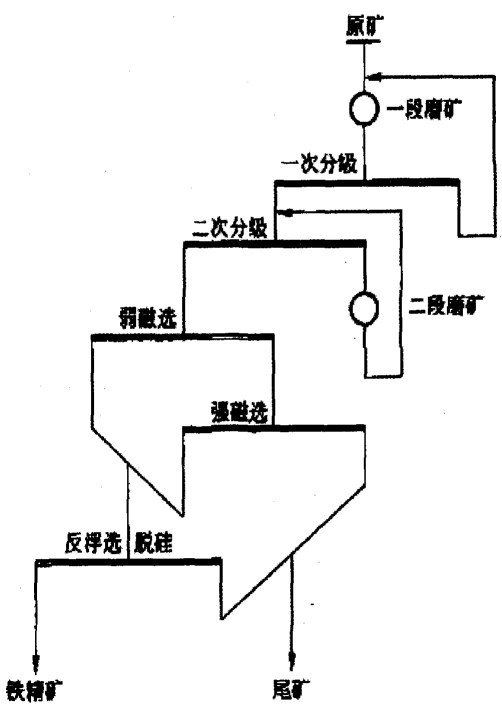

Hematite is a weakly magnetic iron ore, which contains about 50% iron ore. The mineral form is mainly iron oxide, which can be divided into titanium hematite, aluminum hematite, magnesium hematite and water hematite. The main hematite beneficiation process is: continuous grinding-weak magnetic-strong magnetic-anion reverse flotation process. For this type of iron ore, continuous grinding can avoid the quantitative change caused by re-grinding in stage grinding; and the weak magnetic separation-strong magnetic separation process can remove the primary and secondary ore slimes in the ground product, discard a large amount of tailings in advance, improve the material grade for reverse flotation, and promote the further development of the value of anion reverse flotation operation.

The iron content of limonite ore is in the range of 35%~40%. Since limonite is rich in crystal water, if physical beneficiation method is adopted, the grade of iron ore concentrate is difficult to reach the requirement of more than 60%, and limonite is very easy to muddy during the grinding process, and the metal recovery rate is low. At present, the commonly used limonite beneficiation process can be: single beneficiation process, magnetic flotation combined process, reduction roasting-magnetic separation-leaching process, etc. Among them, the single separation process includes gravity separation, magnetic separation, flotation and selective flocculation flotation, etc.

In addition to the above iron ore, it can also be obtained from siderite, ilmenite, etc. However, no matter what kind of iron ore, if you want to obtain a more reasonable iron concentrate grade, the customization of its beneficiation process is very important. It is recommended to conduct beneficiation test analysis to design a reasonable iron ore beneficiation process flow to improve its process efficiency and achieve efficient investment utilization.