15311826613

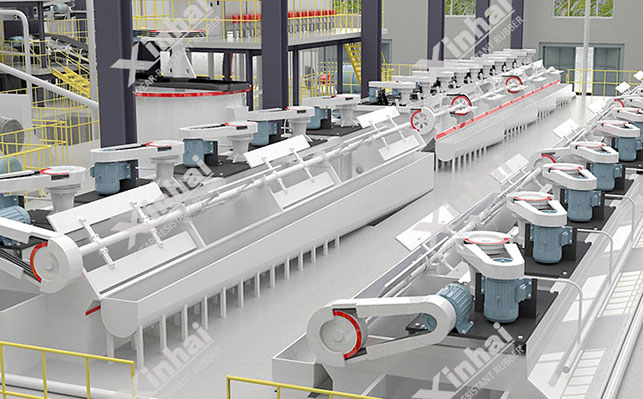

Click to add WeChatFlotation method is one of the commonly used methods for hematite beneficiation. Depending on the properties of hematite ore, different flotation methods are used, so the suitable hematite flotation machines are also different. In hematite beneficiation plants, the commonly used flotation equipment is mainly mechanical agitation flotation machine and inflatable agitation flotation machine. The specific choice depends on the nature of the ore. The following editor will briefly introduce the type of hematite that these two types of flotation machines are suitable for.

This type of flotation machine The separator is a self-priming air equipment. It mainly relies on the stator and rotor in the flotation machine to complete the aerating and stirring operations of the slurry. It has the functions of self-priming and self-priming slurry. There is no need to add an external air supply device or configuration during operation. The lifting pump can suck slurry and air by itself. At present, this type of flotation machine equipment mainly includes SF type, JJF type and BF type.

SF type flotation machine When working, the motor drives the pulley to make the impeller rotate. Under the action of the impeller rotation, the slurry in the impeller cavity generates centrifugal force and is thrown around, forming a negative pressure zone in the impeller cavity. On the one hand, sufficient air is sucked in to mix with the slurry. , on the one hand, the slurry is stirred to mix with the medicine, and at the same time, the foam is refined, so that the minerals adhere to the foam and float to the surface of the slurry to form mineralized foam.

The SF type flotation machine is often used for roughing and sweeping operations in hematite beneficiation plants, and is used in medium and large mineral processing plants. There are many factory applications.

JJF type flotation machine The slurry in the tank can form a large circulation in the lower part and can self-absorb air, but cannot self-absorb slurry. During the operation, the return of the middle ore needs to be transported by a lift pump. When working, the impeller rotates, which will generate vortices in the vertical tube and the guide tube. This vortex forms a negative pressure, sucks the air from the inlet pipe, and mixes it with the slurry sucked in through the guide tube in the impeller and stator area. The mixed The slurry gas moves in a tangential direction from the impeller, and then changes to a radial motion through the action of the stator, so that the slurry is evenly distributed in the tank. The mineralized bubbles rise to the foam layer, and are scraped out from one or both sides to form a foam product.

JJF type flotation machine is rarely used in hematite concentrators, and is mostly used in the range of aeration requirements for copper, molybdenum, etc. Widely used in metallic ores and non-metallic minerals.

This machine has basically the same structure as the SF type and can self-absorb slurry from outside the tank. During operation, as the impeller rotates, a negative pressure zone is formed in the center of the upper and lower blades of the impeller. Air is sucked in from the suction pipe and enters the upper impeller cavity through the central cylinder. The slurry is sucked into the impeller cavity from the groove by the lower blades of the impeller. The slurry and air are After mixing, mineralized bubbles form and float.

BF type flotation machineMore Perform roughing operations in small and medium-sized hematite concentrators.

Hematite mechanical agitator flotation machine:

This type of flotation machine is an external air supply flotation machine. It mainly relies on a mechanical stirrer to stir the slurry and a blower to inflate it. It cannot self-aspirate. When the middle ore returns, a lift pump is required to transport the slurry. In addition, a special conveyor is required. Wind equipment. Currently, the main ones used in hematite beneficiation plants are XCF type, KYF type and XCF-KYF combined type.

This flotation machine is different from conventional inflatable flotation machines and can absorb slurry by itself. When working, the motor drives the impeller to rotate, and the low-pressure air is fed in by the blower. It enters the air distributor through the hollow main shaft, passes through the side wall pores of the distributor, and enters between the impeller blades. The slurry is sucked into the impeller blades from the upper blades, and the slurry and air are mixed. Finally, the mineralized foam rises to the surface of the slurry.

The slurry and gas of the KYF flotation machine are fed from external devices. During operation, after the impeller rotates, the slurry in the tank is thrown around by the impeller, and enters between the impeller blades through the lower end of the impeller. Low-pressure air is supplied from the blower and enters between the impeller blades through air distribution. When the slurry gas is fully mixed, it is discharged from the upper half of the impeller. After being stabilized by the stator, it enters the tank and forms mineralized bubbles that float upward.

KYF Type flotation machineIn hematite beneficiation plants, it is mostly used to process relatively single hematite ore for roughing and sweeping operations.

The XCF-KYF flotation unit uses the XCF type as the suction tank and the KYF type as the straight chute. The two machines are The combination can be configured horizontally, eliminating the infrastructure height difference between operations (300~500mm). There is no need for pumping between operations. The combination of the two machines not only effectively improves the overall flotation effect, but also greatly reduces infrastructure costs and investment costs. In addition, when the two machines are combined, a single-wall backward-inclined blade design can also be used to increase the contact surface between the blades and the slurry, which can form a strong stirring capacity at a lower speed, thus helping to promote the dispersion of the slurry and improve the Restart the ability and reduce the degree of "rollover".

The XCF-KYF flotation unit can be suitable for various large, medium and small hematite beneficiation Factory, doing rough selection, selection and sweeping operations.

The above are several types of flotation equipment commonly used in hematite plants. In actual hematite beneficiation plants, the flotation equipment should be selected according to the ore properties, scale, location, and investment of the beneficiation plant. It depends on the budget and the actual renewal of the user, and cannot be chosen blindly. Xinhai Mining can provide users with mineral processing test services and customize suitable hematite mineral processing based on the test results. Process flowand complete sets of mineral processing equipment. If you have any needs, please feel free to consult Xinhai Mining Equipment.