15311826613

Click to add WeChatAs an important mineral resource for economic development, iron is indispensable. Nowadays, with the high development of resources, easy-to-select, high-grade iron ore is close to depletion. In order to ensure the supply of iron resources, there is a tendency to develop selective hematite ore. Among them, iron ore with high sulfur content is a common refractory type of iron ore. So how to beneficiate and purify this type of hematite? This article will take a certain sulfur-containing mud-containing hematite as an example to introduce its mineral processing technology.

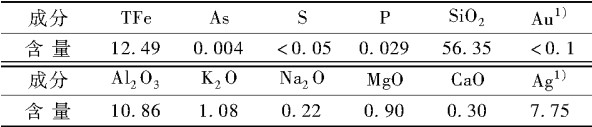

The main valuable element of the ore is iron, with a content of 12.49%; the main impurity component is SiO2, accounting for 56.35%; followed by Al2O3, K2O and MgO. The ore is yellow earthy and powdery to the naked eye.

Among them, the metallic minerals are mainly hematite, with a small amount of limonite and magnetite. There are almost no other metal sulfides such as pyrite, galena, sphalerite, etc. The gangue minerals are mainly quartz. Mainly, followed by clays such as kaolin and a small amount of mica, chlorite, etc. Hematite is mainly in the form of irregular granular aggregates, closely related to limonite and quartz, and closely symbiotic.

According to process mineralogy analysis, it is known that the ore is a typical high-mud and high-silicon hematite ore with complex mineral composition. The target minerals that can be recovered through ore dressing are hematite and pseudo-hematite. Through scanning electron microscopy analysis, it can be seen that hematite and quartz are closely related. Some fine-grained hematite and quartz minerals are intercalated and wrapped with each other. The raw ore contains a large amount of clay minerals (kaolinite) distributed in the hematite. Among aggregates, mud formation inevitably occurs during the crushing and grinding process of raw ore. Therefore, in the process of determining the ore dressing process, in view of the high quality of primary mud and secondary mud in the raw ore, in order to eliminate the impact of mud on subsequent strong magnetic inclusions, it is planned to adopt a pre-sludge process; at the same time, in order to further improve the final iron content According to the grade of the ore, it is planned to use a combined process to purify the magnetic concentrate, so the proposed plan is: raw ore - pre-desliming - strong magnetic tailing - magnetic rough concentrate re-grinding and then separation - reverse flotation desilica aluminum principle Process flow.

Grinding: In order to avoid over-crushing, the raw ore is ground in the form of a graded rod mill. The grinding fineness is -74pm accounting for 54.25%.

Preliminary desliming: After the raw ore is ground, it is gravity separated and classified through a spiral chute to remove muddy impurities in the minerals.

Strong magnetic tailing: After desliming, the product is thrown out through two stages of strong magnetic roughing to obtain iron coarse concentrate and tailings. The suitable intensity of magnetic roughing is 278.66kA/m.

Regrinding of coarse concentrate: Because the fine-grained hematite and gangue minerals in the original ore are seriously intertwined, the grade of the two-stage magnetic roughing concentrate obtained after desliming is low and needs further purification, so the coarse concentrate is used The ore regrinding process has a grinding fineness of -45μm accounting for 73.88%.

Reverse flotation desiliconization: After regrinding and reselection, the coarse concentrate also contains a small amount of harmful elements such as Al2O36.23%, SiO28.15%, P, S, As, etc. which needs to be purified in one step by flotation. The process The method first uses Ca2+ slurrying to activate the silica-alumina minerals, then adds modified starch as a hematite inhibitor, and after complete slurrying, mixed amines are used as cationic collectors to float the silica-alumina minerals.

In the end, this process yielded 51.28% iron concentrate, an iron recovery rate of 38.74%, and the comprehensive mineral processing index reached expectations.

The above is an introduction to the beneficiation process plan of a certain sulfur-containing and mud-containing hematite. In the actual beneficiation plant, how to effectively obtain hematite concentrate needs to determine the appropriate beneficiation process according to its ore properties, so that it can be carried out according to the actual situation. Only through targeted mineral processing can we obtain ideal iron ore grade and efficient return on investment.