15311826613

Click to add WeChatCarbonaceous gold is a gold-containing mineral that contains carbon impurities or gold embedded in carbon, and its embedding state is relatively complex. Gravity separation is a common process in gold ore beneficiation, but gravity separation of carbonaceous gold ore will be affected by many factors, mainly reflected in the properties of the ore, equipment parameters and operating conditions. Understanding these factors will help optimize the gravity separation gold extraction process and improve the gold recovery rate and concentrate grade.

Gold ore particle size: The effect of gold ore particle size on the effect of gravity separation is more obvious. Generally, the larger the particle size, the better the gravity separation effect. Because gold has a large specific gravity, it is easier to separate from gangue minerals if the particle size is coarse. If the gold particle size is less than a certain degree (0.03mm), the difference between the sedimentation velocity and the gangue minerals decreases, and the separation effect is called poor.

Gold ore shape: During the gravity separation process, the shape of the ore will affect its movement trajectory and sedimentation velocity. Gold particles with regular shapes and smooth surfaces are easier to separate according to density differences in gravity separation equipment; while gold particles with irregular shapes and edges may be subject to more friction and fluid resistance, affecting their sedimentation and separation effects. Needle-shaped or flake-shaped gold particles may have abnormal movement trajectories during jigging gravity separation, reducing the separation accuracy.

Carbonaceous material content and properties: When the carbonaceous material content is high, it will interfere with the gravity separation of gold. The density of carbonaceous materials is very different from that of gold, which may affect the sedimentation and enrichment of gold particles. Some carbonaceous materials have certain adsorption properties and may adsorb gold particles, resulting in a lower gold recovery rate. In a carbonaceous gold mine, when the carbonaceous material content exceeds 5%, the gold grade in the gravity separation concentrate decreases significantly.

Ore density difference: The density difference between gold and gangue minerals is the basis of gravity separation. The greater the density difference, the more conducive to the separation of gold. If there are minerals with similar density to gold in the gangue minerals, it will increase the difficulty of gravity separation and reduce the separation effect. For example, if the ore contains more pyrite, its density is close to that of gold, and it is easy to be selected together with gold during the gravity separation process, affecting the grade of the gold concentrate.

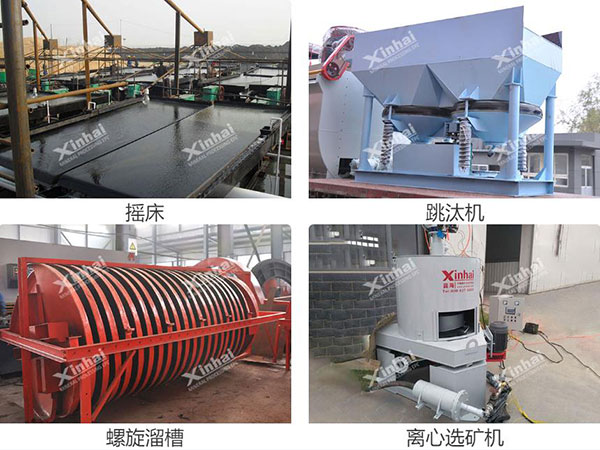

Gravity separation equipment type: Different types of gravity separation equipment have different working principles and application scopes, which have a greater impact on the gravity separation effect of carbonaceous gold ores. The shaking table is suitable for the separation of fine-grained gold, the jig has a better recovery effect on coarse-grained gold, and the chute is often used to process coarse-grained or sandy gold ores. Choosing the right type of equipment can improve the gravity separation effect. When processing fine-grained carbonaceous gold ores, centrifugal gravity separation equipment can more effectively recover gold than chute gravity separation.

Equipment structural parameters: Taking the shaking table as an example, the structural parameters such as the inclination, length, and width of the bed surface will affect the flow speed and distribution of the slurry on the bed surface, and thus affect the gold separation effect. When the bed surface is inclined, the slurry flow rate is fast, which is conducive to the separation of coarse-grained gold, but may cause the loss of fine-grained gold; the length of the bed surface is too long or too short, which will affect the sedimentation and enrichment of gold particles. The parameters of the jig screen plate aperture, stroke, and number of strokes will also have an important impact on the jig re-selection effect.

Feed concentration: Feed concentration has an important impact on the re-selection effect. If the concentration is too high, the viscosity of the slurry will increase, which will affect the sedimentation rate and separation accuracy of the gold particles; if the concentration is too low, it will reduce the processing capacity of the equipment. In jig re-selection, the feed concentration is generally controlled at around 20%-30%, at which time the gold recovery rate and concentrate grade are relatively high.

Water flow rate: In re-selection equipment such as chutes and shaking tables, water flow rate is a key operating parameter. If the water flow rate is too fast, it will make it difficult for the gold particles to settle, resulting in a lower recovery rate; if the water flow rate is too slow, it will affect the processing capacity of the equipment. In chute re-selection, it is necessary to reasonably adjust the water flow rate according to the properties of the ore and the particle size of the gold particles, generally 0.1-0.3m/s.

Feeding amount: If the feeding amount is too large, the pulp layer in the gravity separation equipment will be too thick, affecting the stratification and separation effect of gold particles; if the feeding amount is too small, the production efficiency of the equipment will be reduced. In actual production, it is necessary to reasonably control the feeding amount according to the processing capacity of the equipment and the properties of the ore.

The above introduces the influencing factors of gold extraction from carbonaceous gold ores. In practical applications, these influencing factors should be comprehensively considered according to the specific characteristics of carbonaceous gold ores, and the gravity separation process parameters should be optimized. The appropriate equipment type should be selected and the operating conditions should be strictly controlled to improve the gold recovery rate and concentrate grade. Through scientific and reasonable process design and operation management, the gravity separation effect of carbonaceous gold ores can be effectively improved, providing strong support for the efficient development and utilization of gold resources.