15311826613

Click to add WeChatThe main mineral of a certain lithium ore is spodumene, the gangue mineral is feldspar, accompanied by magnetic iron impurities, and the content of harmful elements sulfur and phosphorus is low. Based on the mineral processing test analysis, the crushing-grinding-desliming-flotation-magnetic separation process flow was designed for the lithium ore dressing plant. Follow the editor below to learn about the detailed process of spodumene and feldspar beneficiation and separation!

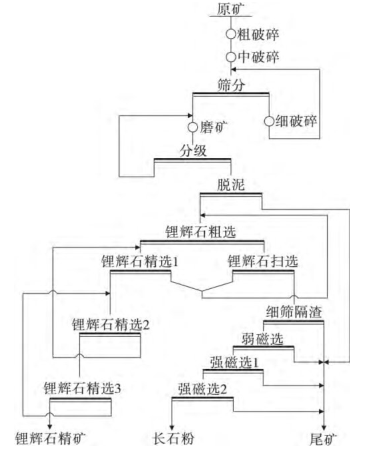

Based on the principle of “more crushing and less grinding”, the crushing stage adopts Three-stage and one closed-circuit crushing processThe ore crushing particle size is controlled below 15mm. The selected equipment is two jaw crushers for coarse and medium crushing, and one cone crusher for fine crushing. , choose a circular vibrating screen for screening operations.

Process:The raw ore is fed from the raw ore bin to the first-stage crusher by the feeder for roughening Crushed, the crushed products are fed to the second-stage crusher by the 1# belt conveyor for secondary crushing. The crushed products are transported by the 2# belt conveyor to the circular vibrating screen for screening. The objects on the screen are returned to the secondary crusher by the 3# belt conveyor. The re-crushing operation is carried out, and the undersize material is transported to the three-stage crusher for fine crushing. The crushed products are sent to the storage silo to prepare for the next stage of grinding. This stage of the process not only reduces grinding energy consumption, but also avoids mud formation caused by large fluctuations in feed particle size and continuous grinding.

The spodumene grinding and classification stage adopts the one-stage grinding process, which is equipped with a Wet grid ball mill and Spiral classifier. The material is transported from the feed silo to the ball mill by a pump for grinding. After grinding, the product enters the classifier for classification, the overflow returns to the ball mill for re-grinding, and the underflow is sent to the next stage for desliming.

The spodumene desliming process adopts Sloping plate concentrator desliming, the thick mud sliding down the inclined plate enters the lower cone, is compressed and dehydrated, and is discharged by gravity to achieve desliming Operation.

The deslimed product enters the flotation operation. The spodumene flotation process uses a Coarse - first sweep - third fine flotation process Before entering flotation, the overflow slurry of the concentrator is first fed into the mixing tank, and at the same time, the medicament is added and stirred evenly before being fed into the flotation machine to complete one coarse and one fine Sweeping three fine flotation process, in which the SF type flotation machine is used in the selection stage, and the medium ore is returned in sequence, and finally qualified spodumene is obtained Concentrate, and the tailings part after flotation enters the magnetic separation stage, and the feldspar concentrate with higher purity (whiter) is obtained through magnetic separation to remove iron.

The magnetic separation stage uses a weak Magnetic - two-stage strong magnetic separation process flow: The main purpose of this stage of the process is to magnetically separate the tailings after flotation to remove iron and select feldspar ore with higher purity. In order to enhance the iron removal effect, high-frequency fine screening is performed to separate slag before magnetic separation, and then feldspar powder is obtained after 1-2 times of strong magnetism.

This spodumene-feldspar separation process has stable production indicators, good economic benefits, high spodumene recovery rate, and feldspar powder white The degree can reach 62.0%, achieving ideal production indicators.

Xinhai Mining can customize suitable spodumene beneficiation process plans and complete sets of spodumene beneficiation processes according to different spodumene ore propertiesSpodumene beneficiation equipment, if you have any needs, please feel free to consult us. At present, the 2 million TPA lithium mine project in Zimbabwe signed by Xinhai Mining and China Mining Resources is in progress. If you want to know more, please wait for subsequent updates!