15311826613

Click to add WeChatMagnetite is one of the important minerals for obtaining iron resources. It contains high iron ore and has strong magnetism. It is an important material for the production of steel. In order to obtain magnetite concentrate, different mineral processing processes must be used, and the process is inseparable from magnetic separation equipment. So what are the commonly used magnetic separation equipment for magnetite?

At present, common magnetic separation equipment in mineral processing plants include magnetic drums, cylindrical magnetic separators, magnetic separation columns, magnetic screens, magnetic desliming tanks, demagnetizers, etc.

The magnetic drum is one of the commonly used equipment in magnetite beneficiation plants. It is also called a magnetic pulley and is often used to separate rich magnetite ores. Selection and rough selection of tail casting operations.

When this type of magnetic separation equipment is magnetically separated, the upper limit of the selected particle size is 100mm, and the lower limit of the selected particle size is 10mm. The processing capacity of the single machine depends on the selected particle size of the feed material, and the upper limit of the processing capacity is 250t/(h·m ).

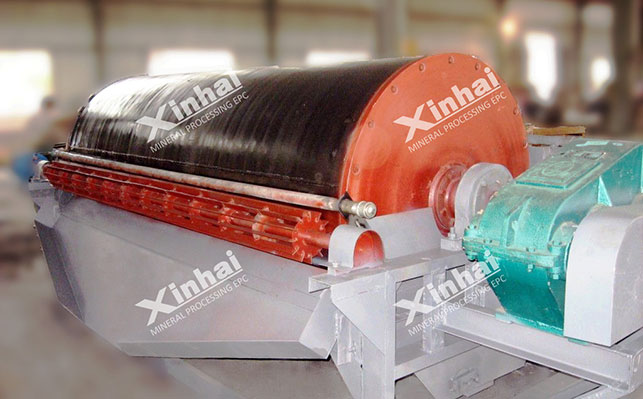

Cylindrical magnetic separators are available in dry type and wet type. The selection needs to be based on the mineral processing Depends on the environment.

Dry cylindrical magnetic separator: It is a magnetic separation equipment that adopts a multi-pole head radial magnetic pole arrangement and an open magnetic system structure. It is mainly used for dry tailing of fine-grained magnetite or dry separation in water-scarce areas. The upper limit of the selected particle size is 30mm, and the lower limit of the selected particle size is -200 mesh (-0.074mm). The content is ≤40%. The processing capacity of a single machine also depends on the selected particle size of the feed material, and the upper limit of the processing capacity is 20t/(h·m).

Wet cylindrical magnetic separator: also adopts the radial arrangement of multi-pole heads, Magnetic separation equipment with open magnetic system structure. For different operations such as rough selection, selection or sweeping, the surface magnetic field distribution and peak magnetic field intensity of the sorting area change accordingly, and different types of sorting grooves (cocurrent, countercurrent and semi-countercurrent) can be selected. The upper limit of the selected particle size is 10mm, the lower limit of the selected particle size is -200 mesh (-0.074mm) and the content is ≤90%. The processing capacity of a single machine depends on the selected particle size of the feed material and the sorting groove type. The upper limit of the processing capacity is 60t/(h·m).

The magnetic separation column is a kind of magnetic separation column that uses electromagnetic weak magnetic field Magnetic-gravity mineral separation equipment combining magnetic system and separation column. The multi-stage alternating solenoid magnetic field is used to alternately produce magnetic aggregation and loosening of fine-grained strong magnetic mineral particles, while the rising water flow effectively removes monomer gangue or poor conjoined particles with a smaller specific gravity from the feed material. This equipment is mainly used for the beneficiation of fine-grained magnetite to improve concentrate grade and separation efficiency. At present, due to the limitations of the equipment structure, the processing capacity of a single machine is low.

Magnetic screen is also a magnetic-heavy combined sorting equipment. After utilizing the effective agglomeration of magnetite in a weak magnetic field, a special sieve installed in the magnetic field is used to discharge the magnetic materials from above the sieve, and the gangue and poor conjoined bodies are discharged from below the sieve, thereby achieving effective sorting. This equipment is mainly used for magnetite beneficiation operations to improve concentrate grade and separation efficiency. This equipment also has the disadvantage of small single-machine processing capacity due to structural limitations.

The magnetic desliming tank is a magnetic-gravimetric separation equipment commonly used in magnetite beneficiation plants. It is mainly used to remove fine-grained gangue and slime, and is sometimes used to dehydrate magnetite, so it is also called a magnetic dewatering tank. The magnetic system structure of the magnetic desliming tank mainly includes several structural forms: lower permanent magnet system, upper permanent magnet system and upper electromagnetic magnetic system. The magnetic field distribution of the upper permanent magnet and electromagnetic magnetic system magnetic desludging tank is basically the same, and its water supply method It is different from the magnetic desliming tank of the lower magnetic system.

The demagnetizer uses an alternating magnetic field to cause the magnetized magnetite particles to lose their residual magnetism to improve the next separation. Separation accuracy of the job. Generally, the demagnetization operation of the coarse concentrate is carried out before the coarse concentrate of the first-stage magnetic separation of magnetite enters the second-stage grinding or second-stage beneficiation.

The above six types of magnetic separation equipment are widely used in magnetite beneficiation plants. The specific equipment selection should be based on the properties of magnetite ore. Only by selecting suitable equipment can the magnetite concentrate be maximized. mineral products. In addition, the above equipment can also be used for the separation of other magnetic minerals, or for the removal of iron from minerals.