15311826613

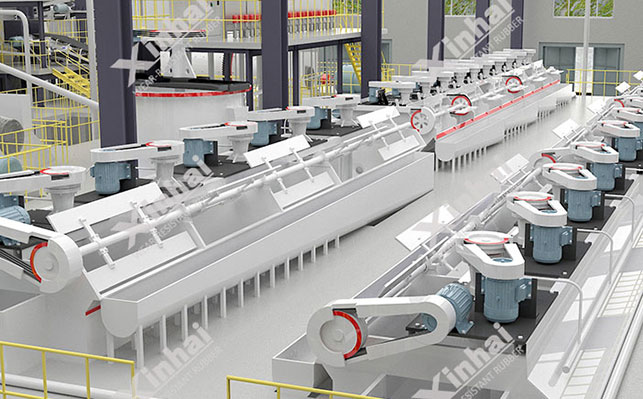

Click to add WeChatThe flotation machine is the main equipment for flotation operations in the mineral processing plant. According to the mineral properties and other characteristics of the mineral processing plant, it can be designed in two types: ladder configuration and horizontal configuration. Below we introduce the difference between horizontal configuration and ladder configuration, and the difference in energy consumption during operation.

Horizontal configuration of the flotation machine: The flotation machine is installed on the same horizontal plane, and the medium ore foam returns in the operation room. This is achieved through the self-priming of the flotation machine. For flotation processes with large foam returns, sticky foam, and poor fluidity in medium ores, the horizontal configuration of the flotation machine can reduce the energy consumption of the flotation operation by 5% to 10%.

Stairway configuration of the flotation machine: There is a certain height difference between different operations of the flotation machine (such as a ladder shape, the height difference is about 4m), and the return of the medium ore foam between operations This is achieved through a pump.

After the flotation process is determined, the specifications and quantity of the flotation machines remain unchanged, and the power consumption of the flotation operation depends on the flotation machine. Configuration methods, different configuration methods have a great impact on the energy consumption of flotation operations, and the flotation machine is determined according to different flotation processes The configuration method is very important.

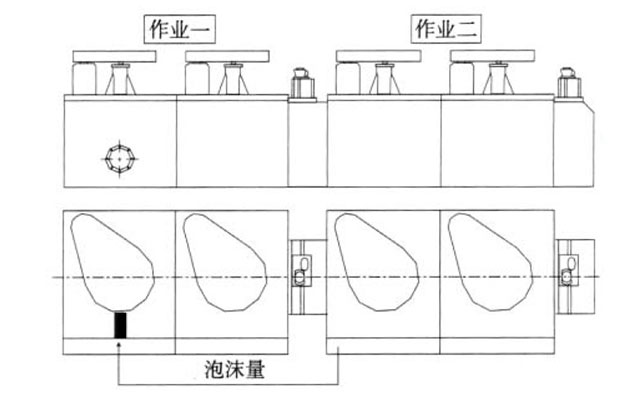

Horizontal configuration means that flotation machines with different operations are installed in the same On the horizontal plane, the medium ore foam can be completed by self-priming of the suction tank flotation machine in the working room. As shown in the picture:

For the energy consumption of the entire flotation operation, the power of the scraper motor, the intermediate box and the tailings box motor are the same as Compared with the power of flotation machine, it can be ignored, so the power consumption is less.

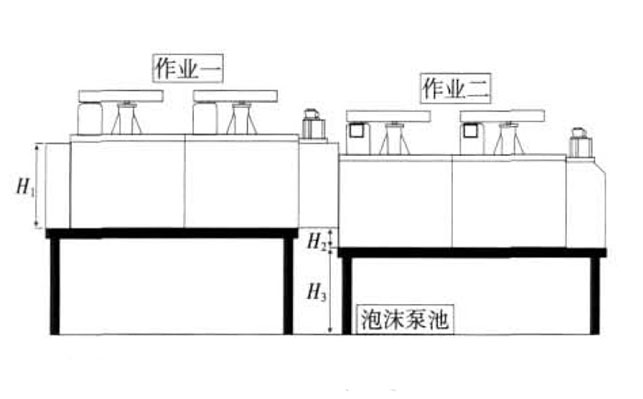

Ladder configuration means that the flotation machines for different operations are not installed on the same level. There is a height difference between each flotation operation. The height of the previous operation A configuration in which the slurry flows to the next operation by gravity and the foam in the middle ore is returned by a foam pump. When configured in a ladder, the medium ore foam first flows by gravity to the foam pump pool on the ground, and then returns to the ore feeding box or intermediate box of the previous operation through the foam pump. As shown in the figure:

When configuring the ladder, ignore the power of the scraper motor, intermediate box and tailings box motor. However, the power of the pump cannot be ignored, so the energy consumption is relatively high.

Overall, the horizontal configuration saves 9.93% more energy than the ladder configuration. At a cost of 0.5 yuan per kilowatt-hour of electricity and calculated on a 330-day basis, the company can save about 283,000 yuan in electricity bills a year.

However, for mineral processing plants, horizontal configuration may not be suitable for all mineral processing plants. Therefore, it is necessary to design based on mineral processing tests and select a suitable configuration method to obtain more economic benefits.