15311826613

Click to add WeChatCarbonaceous gold ore is a type of gold ore that is more difficult to select. Its main characteristics are that carbonaceous materials adsorb gold and the gold embedding state is complex. There are flotation, gravity separation, cyanidation and other methods for gold extraction. This article will focus on the flotation gold extraction technology for carbonaceous gold ore.

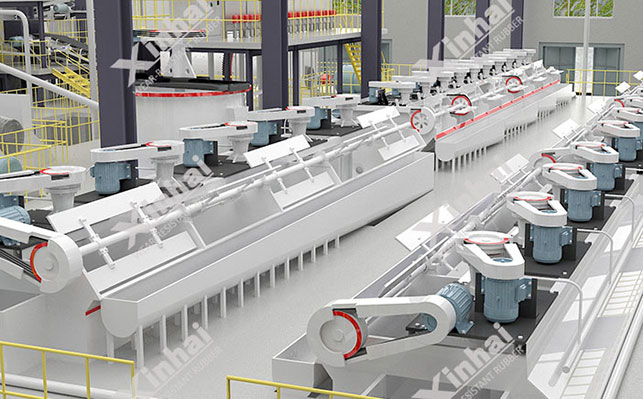

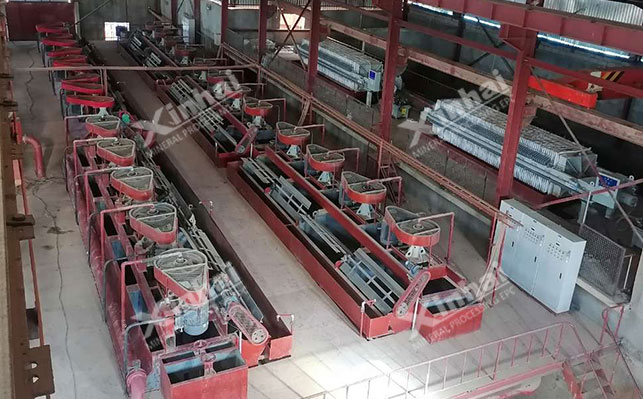

Flotation can use the difference between the surface properties of reagents and minerals to overcome carbon interference, enrich and separate gold, and improve the gold recovery rate and concentrate grade. In view of the special properties of carbonaceous gold ores, the flotation process needs to select the appropriate flotation method according to the coexistence relationship between carbon and gold. At present, the common flotation gold extraction technologies include direct flotation, preferential flotation carbon refloatation, mixed flotation carbon gold extraction, flotation-gravity separation combined gold extraction, flotation-cyanide combined gold extraction and flotation gold extraction with the addition of inhibitors.

It is suitable for carbonaceous gold ores with simple symbiotic relationship between carbon and gold and coarse gold minerals. By taking advantage of the difference in physical and chemical properties of gold and gangue mineral surfaces, flotation agents are added to make the surface of gold minerals hydrophobic, attach to bubbles and float up, and separate from gangue minerals. In a carbonaceous gold mine, gold mainly exists in the form of natural gold with relatively coarse particles. The direct flotation method, the addition of xanthate collectors, and the combination of frothers can effectively enrich gold by flotation to obtain gold concentrates with high gold grade and recovery rate.

If the relationship between carbon and gold in carbonaceous gold ore is relatively simple, and carbon has a greater interference on gold flotation, the method of preferential carbon flotation can be used first to float out the carbonaceous material to reduce its impact on gold flotation, and then flot gold from the floating carbon tailings. Prioritize flotation was used for a carbonaceous gold ore with a gold grade of 2.5g/t and a carbon content of up to 12% in Gansu. Carbon was first floated, and then pyrite and other gold-bearing minerals were floated. The obtained flotation carbonaceous gold concentrate had a grade of 41.20g/t and a recovery rate of 49.41%, and the pyrite-bearing gold concentrate had a grade of 28.80g/t and a recovery rate of 41.22%, with a total recovery rate of 90.63%.

When carbon and gold in carbonaceous gold ore are closely related and it is difficult to effectively separate carbon and gold, the mixed flotation carbon-gold method can be used to float carbon and gold together to obtain carbon-gold mixed concentrate, and then the mixed concentrate can be processed. A mixed flotation process was used for a carbonaceous gold ore with a gold grade of 1.18g/t and a carbon content of up to 9.42%. Under the conditions of grinding fineness -0.074mm90%, 1 roughing 4 sweeping 4 fineness, the gold concentrate grade was 17.05g/t and the recovery rate was 73.25%.

Combining the advantages of flotation and gravity separation, gold is first initially enriched by flotation, and then gravity separation is used to further purify the gold concentrate. Gravity separation can use equipment such as shaking tables and spiral chutes to separate gold according to the difference in density between gold and other minerals. A flotation + gravity separation process was carried out on a carbonaceous arsenic gold mine. The gravity separation used a Nelson concentrator, and the mixed gold concentrate obtained had a grade of 54.41g/t and a recovery rate of 87.35%.

First, obtain gold concentrate by flotation, and then cyanide leaching the gold concentrate to extract gold. Flotation can effectively enrich gold, reduce the subsequent cyanide leaching treatment volume, and reduce reagent consumption and costs. A high-carbon, low-grade gold mine uses flotation gold concentrate + roasting + cyanidation process, and the obtained flotation gold concentrate recovery rate is 83.10%, and the leaching rate after roasting is 93.66%. During the flotation process, the grinding fineness must be strictly controlled to avoid over-grinding that causes mudification of gold minerals and affects the flotation effect. At the same time, according to the properties of the ore, the type and dosage of flotation reagents such as collectors and frothers are reasonably selected to improve the flotation index.

In view of the interference of carbonaceous materials on gold flotation in carbonaceous gold ores, inhibitors are added to inhibit the flotation of carbonaceous materials and improve the flotation selectivity of gold. Commonly used inhibitors include sodium naphthalenesulfonate, kerosene, diesel, etc. Using sodium naphthalenesulfonate to inhibit carbon gold selection in the flotation stage can improve the recovery rate. However, inhibitors such as sodium naphthalenesulfonate may have problems such as environmental pollution and need to be used with caution. When adding inhibitors, the interaction between inhibitors and other flotation reagents and the influence of inhibitors on subsequent gold recovery processes should be fully considered to ensure the efficient operation of the entire flotation gold extraction process.

Flotation gold extraction technology for carbonaceous gold ores is an important means to deal with such difficult-to-select ores. Different flotation methods can effectively overcome the interference of carbonaceous materials and improve the gold recovery rate and concentrate grade. In practical applications, the appropriate flotation process should be selected according to the specific properties of the ore, and the reagent system and operating parameters should be optimized to achieve a reasonable beneficiation effect.