15311826613

Click to add WeChatZinc is one of the important mineral resources for my country's industrial development. It has large mineral reserves and many types, and is often symbiotic with copper or lead. In addition, flotation method or joint beneficiation method is usually used in mineral processing. To be done. When lead oxide ore is flotated, the selection and use of reagents is very important. Commonly used mineral processing reagents are mainly collectors and regulators. This article focuses on the types and characteristics of lead oxide mineral flotation collectors.

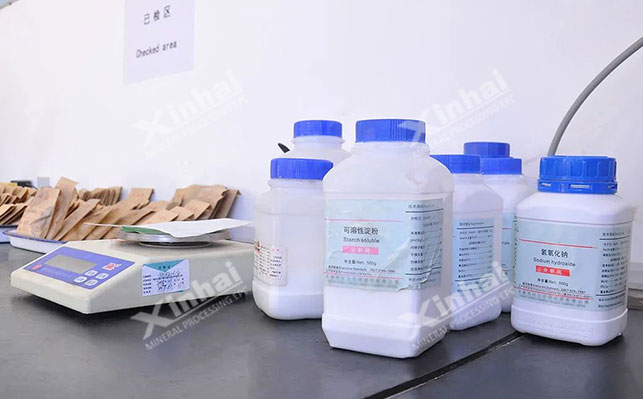

At present, in the process of zinc oxide flotation in mineral processing plants, the commonly used collectors are mainly fatty acids and amines. and xanthate, among which fatty acids mainly include oleic acid, tar oil, oxidized paraffin soap, etc.; xanthate generally uses high-grade xanthate; and amines are mostly fatty amines. According to different classifications, it can be divided into cationic collectors, anionic collectors, chelating collectors and combined collectors.

The anion collectors used in zinc oxide flotation are mainly xanthate collectors, hydroxamic acid collectors, Carboxylic acid collectors, mercaptan collectors, etc.

Amine collectors are the main cation collectors, such as octadecylamine, dodecaamine, etc., which are flotation oxidation A common collector in zinc mines.

can react with metal ions on the surface of minerals to form insoluble chelates to achieve the effect of capturing target minerals. For example, E-5 modified alkylamine zinc oxide chelating collector has the advantages of low dosage, low price, strong collection power, and good selectivity. It is used in industrial production and after gravity separation The zinc oxide minerals in the tailings are flotated again to obtain zinc concentrate product indicators with a grade of 32% and a recovery rate of about 85%.

It is a combination of anionic and cationic collectors, that is, amine collectors and xanthate collectors or carboxylic acid collectors combination of agents.

The above four collecting agents are zinc oxide mineral processing The types of chemicals commonly used in factories. In the actual mineral processing process, the specific choice of chemicals and the amount of dosage need to be determined according to the mineral properties and mineral processing capacity. Therefore, it is necessary to conduct mineral processing test analysis to design suitable chemical types and dosages. Can obtain ideal zinc concentrate.