15311826613

Click to add WeChatGold ore flotation process is one of the commonly used methods for gold extraction. It is mainly used to enrich fine-grained gold and sulfide gold-bearing ores with good floatability and polymetallic gold-bearing sulfide ores. So what are the conventional beneficiation processes in the flotation process? Let's learn about it together!

In the gold ore flotation process, the conventional process flow includes: crushing and screening-grinding classification-flotation separation and concentration filtration.

The gold ore crushing process is mainly a crushing and screening process. Usually two-stage closed-circuit crushing is used. The mined minerals are sent to the storage bin by the stone transporter, and are fed into the first crusher by the (trough or swing) feeder for coarse crushing. The crushed products are sent to the screening machine by the belt conveyor. The screened material returns to the first coarse crushing crusher, and the screened material enters the second crusher for fine crushing. After fine crushing, the product is sent to the next stage by the conveyor.

The grinding stage is a grinding and classification process. According to the particle size of the gold ore, there are generally one-stage grinding and classification and two-stage grinding and classification processes. This article takes the first-stage grinding and classification as an example to introduce the process: the qualified ore particles after crushing are fed into the grid ball mill by the feeder for grinding, and the product is fed into the hydrocyclone by the pump for classification. The overflow returns to the ball mill for re-grinding, and the bottom flow enters the flotation stage.

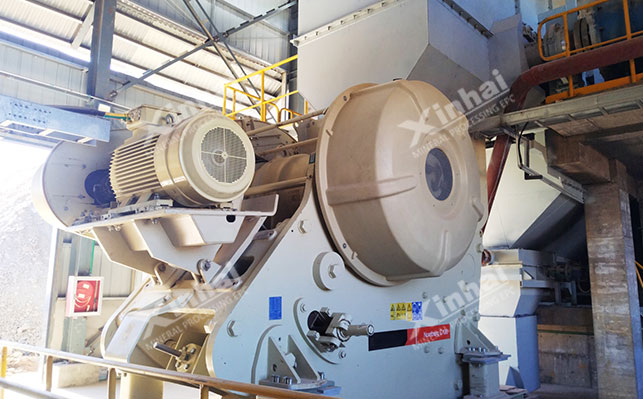

Flotation generally depends on the properties of gold ore, and there are many options. This article mainly introduces the roughing-concentrating process of gold flotation. The minerals after grinding and classification are fed into the stirring tank by the pump, and the slurry is first added. After the medicine and the slurry are fully mixed, they are fed into the flotation machine for stirring and flotation. After roughing-concentrating, qualified gold concentrate is obtained, and the rest is tailings.

Gold concentrate dehydration is an important link, and it can enter the smelting system after dehydration. In the dehydration process, a variety of dehydration equipment is generally used to concentrate and drain the gold ore to meet the water content requirements. It is generally a concentration + filtration process: the gold concentrate slurry is fed to the high-efficiency concentrator for concentration, so that the water content of the concentrate is as low as 45% or less, and then fed to the filter press for dehydration again, and the final water content is as low as 15%, and then sent to the concentrate warehouse by the belt conveyor for storage, waiting for subsequent smelting.

The above are the process steps of conventional gold flotation. In the actual ore dressing process, how gold is floated depends on the properties of the gold ore. Therefore, it is recommended to conduct ore dressing test analysis first, and design a suitable flotation process and a complete set of gold flotation equipment according to the analysis results, so as to obtain an ideal return on gold mine investment.