15311826613

Click to add WeChatAfter gold is mined, it is almost necessary to carry out sorting and processing to obtain high-grade gold concentrate. Every link in the beneficiation process is particularly important. Among them, the purchase of beneficiation equipment requires a lot of energy and cost, which has an important impact on the gold beneficiation effect. Therefore, comprehensive preparation work is required for the purchase of equipment for gold beneficiation plants. In this article, we will introduce some key steps and considerations.

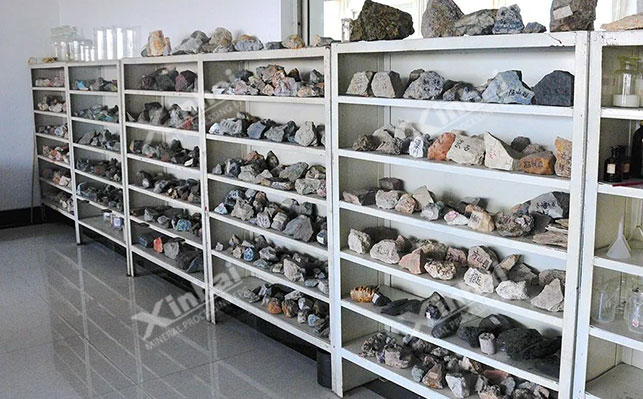

The preparation work before purchasing gold mining equipment mainly includes analyzing the characteristics of the ore and determining the appropriate ore dressing process. This process is critical and important. The analysis of ore characteristics has a decisive influence on the selection of gold ore dressing equipment, because it is directly related to the determination of the ore dressing process and the optimization of equipment configuration.

Before starting work, you need to understand the ore's type, grade, particle size distribution, gold form and occurrence state. This part of the work can be tested in the laboratory, including ore selectivity tests, to determine the appropriate beneficiation process and equipment configuration. The gold content and grade will affect the selection of beneficiation technology. The ore's particle size distribution, density, hardness and other physical properties determine the selection of crushing and grinding equipment. For example, harder ores may require larger crushers and grinders.

If the ore dressing test determines the main equipment of the gold ore dressing plant, then the mine design plays a decisive role in estimating the various auxiliary equipment of the gold ore dressing plant, including the connection of each main equipment and the monitoring and control system applied to the entire set of equipment. Through the mine design, the number and series connection of each equipment in the ore dressing plant can be more intuitively grasped, which is conducive to reducing the investment and loss in the actual installation and construction, and reducing the construction cost.

Choose appropriate equipment according to the process flow, such as jaw crusher, ball mill, flotation machine, desorption electrolysis system, concentrator, belt chute, shaking table, spiral chute, jig, gold placer centrifugal washing machine, spiral concentrator, etc. The factors that need to be considered in the purchase stage are also relatively complex, mainly including cost-effectiveness, comparison and evaluation of suppliers, etc.

When purchasing equipment, priority should be given to those that can improve production efficiency. Not only the initial purchase cost, but also the operating cost, maintenance cost and energy consumption of the equipment should be considered. Choosing equipment with a high cost-effectiveness ratio can achieve cost recovery in the long run by saving energy and reducing maintenance costs even if the initial investment is high. Not only that, the equipment's production capacity, efficiency, energy consumption, convenience of operation and maintenance and cost-effectiveness should also be considered.

On this basis, it is necessary to investigate and evaluate potential equipment suppliers, including their technical strength, product quality, after-sales service and price. Conduct market research and compare the quotations and services of different suppliers. According to the detailed investment budget, different links are allocated, including equipment purchase costs, transportation costs, installation costs, commissioning costs, etc.

The purchase of gold beneficiation equipment is a complex and crucial task, which directly affects the beneficiation effect and economic benefits. Before purchasing, detailed preparations must be made, including ore characteristics analysis and determination of beneficiation process flow, which have a decisive influence on equipment selection. During the purchase process, the production efficiency, cost-effectiveness, supplier strength, product quality and after-sales service of the equipment must be comprehensively considered. Correct equipment selection can optimize the production process, reduce operating costs, and improve long-term investment returns.