" Shandong Xinhai Mining Technology & Equipment Inc. is deveoted to providing tailored, professional and intelligent mine EPCM+O service covering design and research, equipment manufacturing and procurement, civil construction, equipment installation and commissioning, mine management and operation service.

Lead and zinc are important non-ferrous metals widely used in various fields. Therefore, the rational development and processing of lead-zinc ore resources is of great significance to the development of the industrial economy. Based on different mineralization processes, lead-zinc ores can be classified into different types. In actual production, adopting appropriate beneficiation technologies can effectively improve the recovery rate and economic benefits of lead-zinc ore. The following will introduce the operations at different stages of the lead-zinc ore beneficiation process, helping you better understand the utilization pathways of lead-zinc ore and deeply grasp the core logic of the lead-zinc ore beneficiation process.

Phosphate ore is a strategic non-renewable resource for ensuring food security and industrial development, used in agriculture, industry, and new materials. Global demand is rising, but phosphate ore is mostly low-grade and complex, with many impurities. Efficiently obtaining high-grade phosphate ore relies on beneficiation, with flotation being the primary method. The following introduces common phosphate ore flotation methods and the selection of flotation methods for different types of phosphate ore.

With gold prices remaining high, is your tailings pond still a cost center? How can the residual gold and other valuable elements be accurately recovered? Scientific gold tailings reprocessing technology is key to revitalizing this "urban mine."

With gold prices running high, previously difficult-to-develop low-grade gold mines have become new wealth opportunities. For investors, the key to success lies in accurately selecting gold ore beneficiation technology, which directly determines your resource monetization efficiency and return on investment. Let us help you master core beneficiation solutions, make precise plans, and directly transform market opportunities into tangible profits.

Copper-lead-zinc ores are common polymetallic mineral types and important raw materials for the non-ferrous metals industry. Their ore types are complex, often existing as sulfide ores, oxide ores, or mixed ores. Due to the close association of copper, lead, and zinc minerals and their similar floatability, effective separation is quite difficult. This article will introduce copper-lead-zinc ore separation and beneficiation technologies from multiple perspectives.

Mica is a layered hydrous aluminosilicate mineral containing various elements such as potassium, aluminum, magnesium, iron, and lithium. It has applications in many industrial fields, and with technological development and industrial progress, the demand for mica continues to rise. This article provides a detailed introduction to mica ore beneficiation methods!

The mining methods for mica need to be selected based on the deposit type, occurrence state, and ore characteristics. The main mining principle is "protecting the integrity of mica crystals," prioritizing mining methods that minimize ore disturbance. Currently, there are two main categories: open-pit mining and underground mining.

In the gold mining industry, finding low-cost, high-efficiency gold extraction processes has always been a key driver of industry development. With the gradual depletion of high-grade gold ore reserves, the development and utilization of low-grade gold ore (typically referring to gold grades in the range of 0.5~3 g/t), as well as tailings and waste rock, has indeed become a focus of industry attention. Heap leaching gold extraction, with its low cost and high efficiency, provides a feasible path for the effective utilization of low-grade gold ore. Let's explore heap leaching gold extraction technology and the secrets to its low cost and high efficiency.

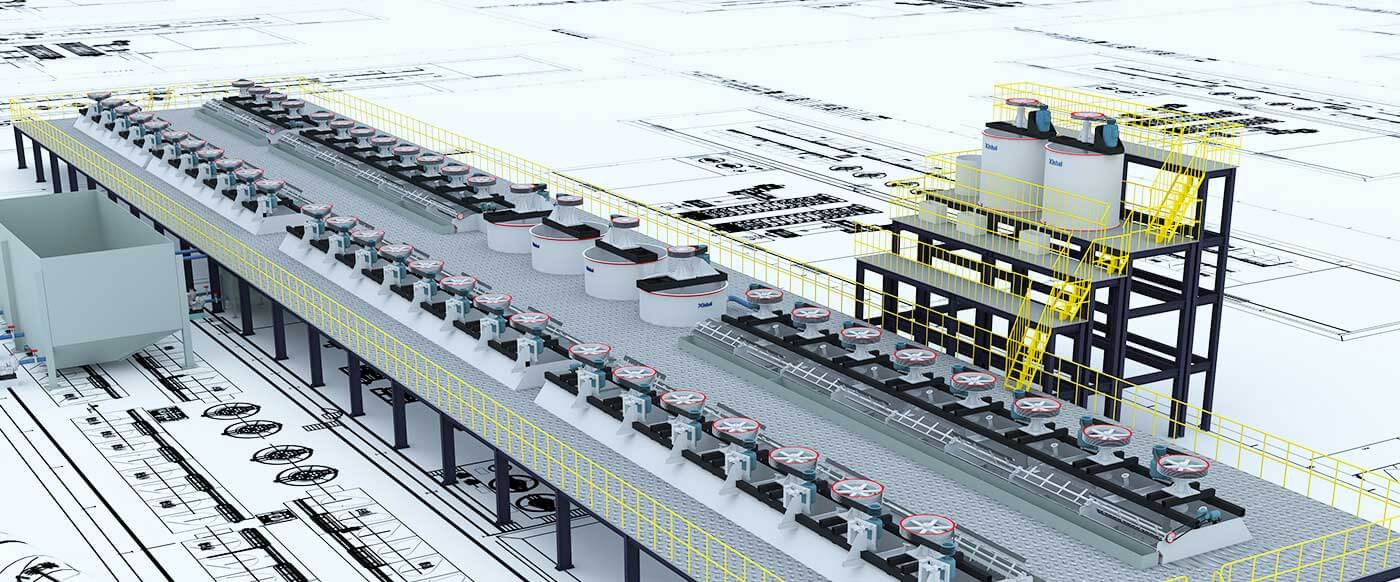

Xinhai Mining installs customized mineral processing equipment, provides overall mineral processing solutions and mine operation management services, helping you avoid various problems in the mineral processing plant, improve the production efficiency of the mineral processing plant, reduce the investment cost of the mineral processing plant, and achieve low investment and high returns.

Stand-alone equipment/complete set of mineral processing equipment for your choice

The mineral processing process plan is customized according to the needs

02Xinhai installation and commissioning team, tracking and guidance

Xinhai Mining can produce various gold ore beneficiation equipment, lithium ore, spodumene, iron ore, copper-lead-zinc, molybdenum ore, nickel ore, manganese ore, rare earth ore, quartz sand and other single and complete sets of mineral processing equipment, in addition to Auxiliary accessories for production equipment, etc.

Xinhai Mining can customize suitable process flow, suitable mineral processing equipment and determine the model specifications of each equipment based on user needs, mine mineral types and actual dressing plant conditions.

Xinhai Mining Assembly has a professional installation and commissioning management service center, packaging and shipping center, and project management and operation center to provide customers with complete pre-sales, in-sales and after-sales services.